„Effective Heat and Temperature Control“ is HOBRA’s comprehensive mark, under which all the company’s products and services in refractory and insulation applications are identified. In essence, it is a marketing project which covers everything HOBRA manufactures, offers and supplies in these spheres.

Efective heat and temperature control

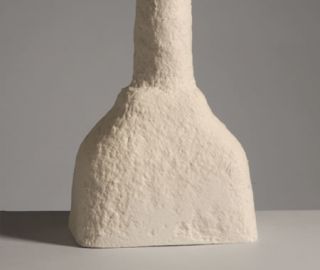

TVAROFORM

TVAROFORM refractory and thermally insulating shaped forms are manufactured from aluminosilicate fibers suspended in water with the addition of an inorganic binder and a small quantity of organic binders.

Solid shaped forms are manufactured from this suspension using molds and vacuum. One (mold) surface is even, to delimit the defined dimensions precisely. The other surface is slightly uneven. The application temperature is up to 1,260°C or 1,430°C depending on the type of the fiber used.

TVAROFORM shaped forms are used as thermally insulating materials at temperatures up to 1,200 °C. They protect the various parts of furnaces and structures well against high temperatures and prevent heat dissipation. The most suitable applications are in the metallurgical, engineering and glass industries, as well as in power engineering (e.g. in the manufacture and repair of different types of furnaces, boilers, fireplaces, etc.). When shaped forms are used for temperatures under 890°C, they should be fired for 4 hours at 890°C. This heat is necessary to burn out the organic binder and start the function of the inorganic binder. We are able to produce specific tailor-made types and dimensions of shaped forms according to precise drawings.

TVAROFORM refractory shaped forms are used in the following applications:

- Foundry

- Sprue holes for the Lost Foam technology (the most frequent application)

- Pouring runners and inlets

- Melting pots

- Insulation of furnace inlet holes and spouts

- Insulation of risers

- Filter carriers

- Metallurgy of ferrous and non-ferrous metals

- Substitute for asbestos materials (seals, protection, etc.)

- Metallurgy

- Internal and external lining for all furnace types

- Insulation of ladles and cars

More detailed information about this product, including technical data, can be found in the downloadable documents below.

Documents to download:

TVAROFORM (175.1KB, .PDF)

Applications:

Metallurgy and foundry

Engineering

Glass and Ceramics

Civil Engineering

.jpg)

.jpg)

.jpg)