„Effective Heat and Temperature Control“ is HOBRA’s comprehensive mark, under which all the company’s products and services in refractory and insulation applications are identified. In essence, it is a marketing project which covers everything HOBRA manufactures, offers and supplies in these spheres.

Efective heat and temperature control

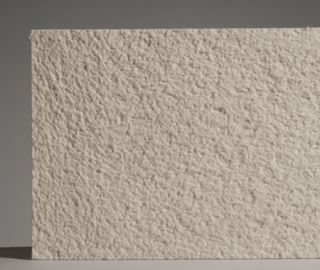

SIBREX®140

SIBREX®140 refractory boards are manufactured from ceramic, aluminosilicate fibers bonded with combined inorganic and organic binders and are used as thermally insulating materials at temperatures up to 1,100 °C.

The soft boards of a volumetric weight of 140 kg/m3 are used predominantly in technological parts of structures for the insulation of unprotected and slightly curved surfaces.

Due to high temperatures, the organic binder burns out, partially reducing the board consistency and strength. For this reason, the organic binder is combined with an inorganic one, as even a small quantity of inorganic binder improves the board consistency considerably in heat, although it does not reach the consistency level of boards bonded solely with inorganic binders. SIBREX®140 boards can be used advantageously as thermal insulation for the protection of structures against high temperatures and heat dissipation, e.g. for the insulation of air heaters, blast and glass furnaces, etc. High energy economies are achieved in all applications, especially in cyclically working equipment, where considerably lower heat accumulation in comparison with conventional lining applies in addition to the board insulation properties. The boards can be glued to existing ceramic furnace lining by means of Soudal refractory or stove-making putty (commonly available from paint and varnish retailers).

SIBREX®boards are manufactured using the paper-processing technology from a water suspension consisting of loose aliminosilicate fibers, combined binders and admixtures.

SIBREX® 140 boards are used in the following applications, but are not limited to them:

- Metallurgy

- Insulation and repairs of all furnace types

- Expansion insulation behind brick (concrete) masonry

- Insulation of ladle and furnace lids

- Insulation of mixers, heaters, etc.

- Boiler production

- Insulation of doors and exhausts

- Brick industry

- Insulation and sealing of furnace cars

- Expansion components of furnace insulation

- Other

- Insulation of heating furnaces and parts of glass tanks

- High-temperature sealing for all applications

- Fire and heat radiation protection

- Metallurgy of ferrous and non-ferrous metals

- Fire-resistant doors

More detailed information about this product, including technical data, can be found in the downloadable documents below.

Documents to download:

SIBREX® (249.8KB, .PDF)

Applications:

Metallurgy and foundry

Engineering

Glass and Ceramics

Civil Engineering